Preventive Maintenance:

Save Your Fleet Money and Avoid an Operational Root Canal

That’s a fancy way of saying that it’s better to try to keep a bad thing from happening than it is to fix the bad thing after the fact. You install smoke alarms to stay safe and prevent disasters, invest in your children’s education to ensure they can take care of themselves, and you go to the dentist for check-ups to avoid a costly root canal.

Preventive Maintenance:

Never More Important

Franklin’s proverb should be prominently displayed on every fleet manager’s desk, particularly now. Preventive maintenance has never been more important. The challenges created by the COVID pandemic—lack of or delayed replacement parts, extended service lives of unreplaced units, inflation, skyrocketing fuel, equipment and labor prices and now, ramped-up demand—have dramatically increased the cost of operating a trucking fleet. According to the American Trucking Association, maintenance costs rose 3.7% in the fourth quarter of 2021 and were up more than 10% from the previous year, showing no signs of slowing soon.

Investing time, energy, and resources before a significant issue arises reduces the risk and cost of consequences on the back end. For fleet managers, investing in preventive maintenance can reap significant rewards, from cost savings to reduced vehicle and driver downtime, to greater operational efficiency. It can be the difference between replacing a $10 part upfront or spending thousands on replacements and unscheduled downtime.

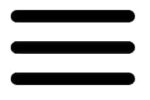

The right technology alerts you of potential issues before they become costly problems. Preventive maintenance tools provide volumes of data that can help keep vehicles rolling smoothly between regularly scheduled shop visits and avoid pending parts and system failures.

Regardless of fleet size, creating the right preventive maintenance system can help fleet managers:

Reduce equipment downtime

Identify and prioritize the trucks that require service

Reduce breakdowns

Lower service and towing expenses

Reduce cascading damage

Better customer service and on-time performance

GPS Tracking is the Key to Preventive Maintenance

Vehicle downtime due to unplanned maintenance is costly for any organization. Unexpected repairs take away from the bottom line, especially if the repairs must be made more than once. Along with the cost of the repair itself, keeping track of maintenance by hand is also costly when considering the person hours it takes to enter and retrieve the information. This process involves someone going out to the vehicles each day to write down odometer readings or testing for an issue and researching diagnostic codes.

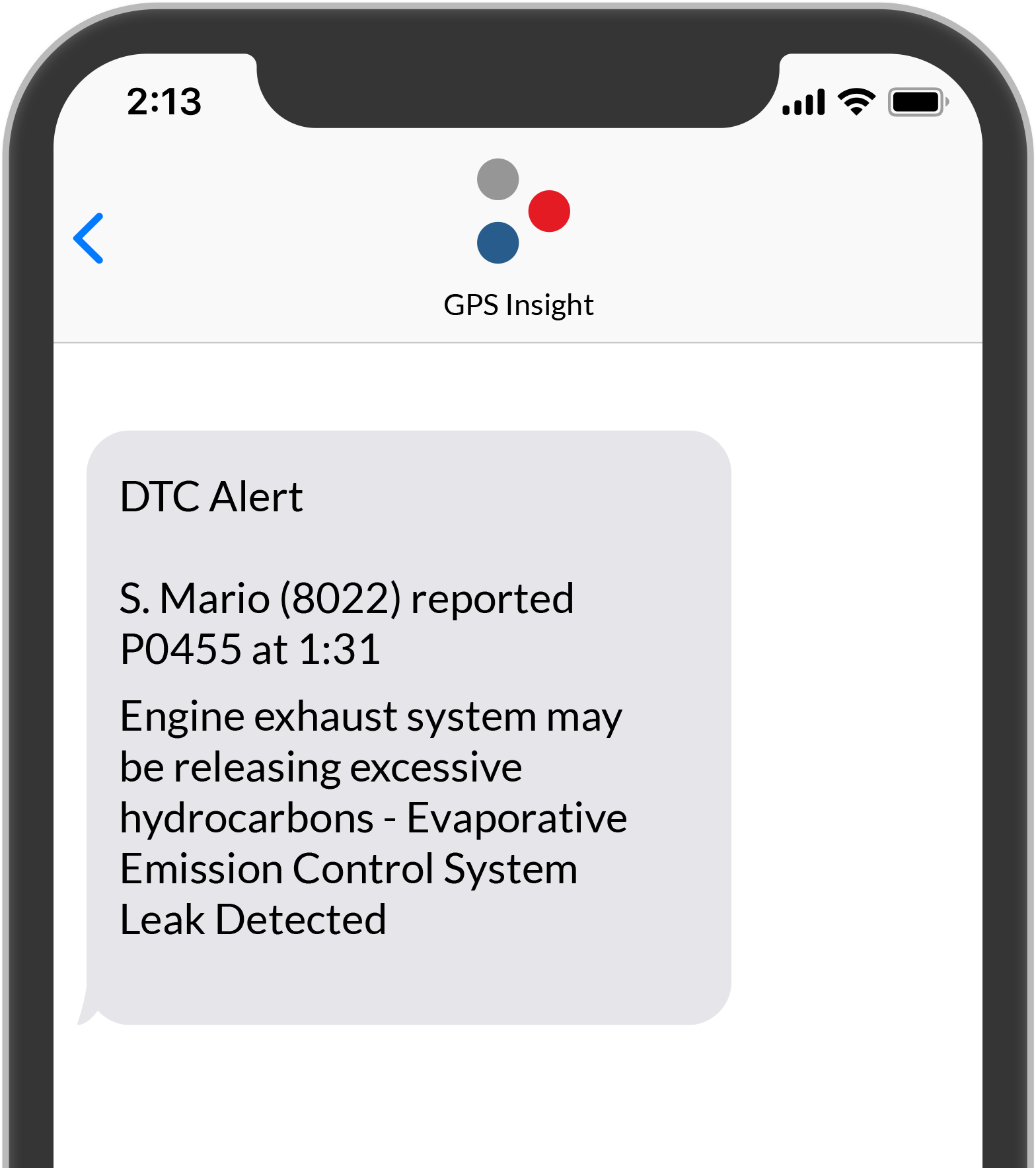

That’s why fleets have turned to GPS tracking to improve maintenance management. GPS tracking software will automate any service that needs to be completed for vehicles and assets—from oil changes to tire rotations, and even car washes to keep wrapped vehicles clean. GPS tracking software provides automated reminders when service is due, as well as a digital log of the information such as service costs and any additional service that needed to be performed. Service intervals can be set based on mileage, run-time hours, or even dates (this can be used for inspections, registrations, and warranty renewals.)

Automating maintenance removes the guesswork and manual process of keeping your fleet up to date.

Overuse of vehicles and assets will reduce their lifecycles, meaning they need to be replaced sooner than expected. Overuse happens in several ways; for instance, employees may use their favorite vehicles and assets over others—shortening the lifecycle and leaving others unused for long periods of time. Most wear and tear come from how vehicles or assets are used.

Preventive maintenance is set up through intervals either based on the odometer, runtime, or a specified date. Common preventive maintenance includes oil changes, tire rotations, or vehicle registrations and inspections. Preventive maintenance also allows for record keeping of service costs, and any additional notes necessary. This can be extremely useful when managing various size service intervals—i.e., rear-end service is to be completed at 20,000 miles while transmission service is due at 25,000 miles, etc.

Even well-organized businesses overlook one—or even more—of these at one time or another. GPS tracking can help you manage your vehicle maintenance and reduce the odds of breakdowns hurting your business.

Improved Maintenance Scheduling

The ability to run a cleaner and healthier fleet is one of the most important advantages of GPS tracking.

GPS Insight has a maintenance scheduling module that enables fleet managers or maintenance managers to track maintenance services easily by sending a notification when service is due. A report can also be generated to provide an overview of upcoming or overdue maintenance.

The use of a maintenance feature within GPS fleet tracking software will aid in the prevention of breakdowns that could result in lost business, wasted time getting vehicles repaired, and paying your technicians for unproductive time.

An In-Depth Fleet Utilization Report

By balancing how frequently you use your vehicles, you can also lengthen their lives. To help you manage and divide the duty, tracking software provides data on how often your vehicles are on the road.

A fleet utilization report allows you to discover data on trips made, days used, engine hours, mileage, and even which staff members are driving each of the vehicles.

Preventive Maintenance in Action

Ignoring maintenance is a problem that, if not addressed quickly, can lead to very high operating costs, higher risk, and a reduction in revenue. GPS Insight software can make preventive maintenance simple by implementing a maintenance schedule and instituting recurring automated reminders to keep trucks running at peak efficiency.

GPS Insight can put the right tools in place to avoid unnecessary costs and risks associated with poor upkeep and to keep revenue-generating vehicles on the road. For more information on how you can implement a preventive maintenance system to reduce costs, increase efficiency and improve operations, click here.